Oct 07, 2020 by Mark Dingley

These days, a troublesome barcode that won’t scan correctly could be the difference between continuing with a supplier or looking elsewhere. Most retailers have become increasingly intolerant of products that cause scanning errors, but can you blame them?

A barcode that cannot be properly scanned or decoded on the first pass each and every time can cause costly implications for the supply chain. This doesn’t end with the time lost at the cash register or in the warehouse – there is a potential error any time a human has to manually enter data into a system.

So, how can you avoid a scenario involving poor barcode quality?

The answer is barcode verification.

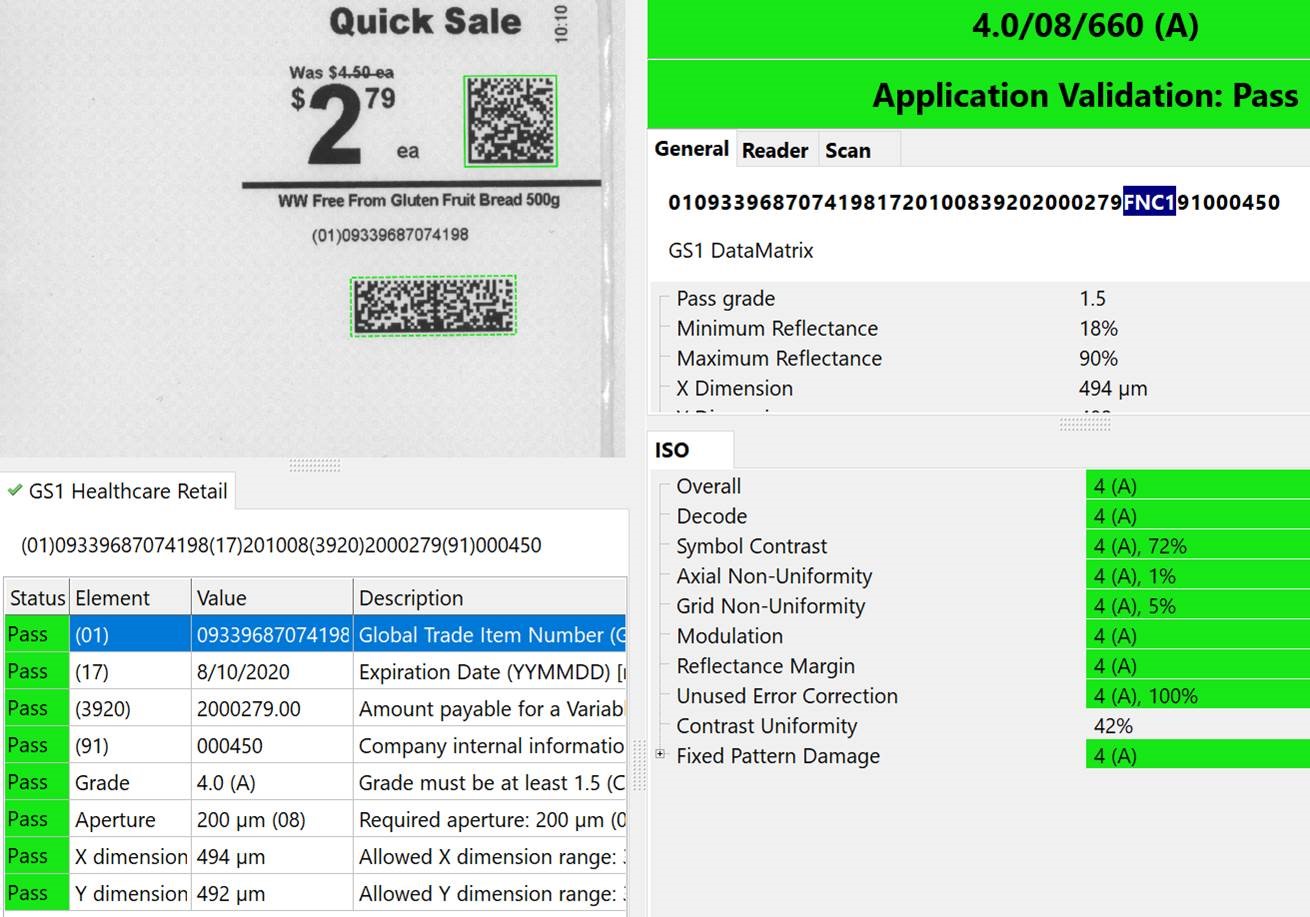

This process neutrally evaluates barcodes, measuring their printed quality to ensure better reading rates. These measurements are performed according to international (ISO) standards, which have been developed to set the benchmark for quality and readability based on variables often found in stores.

Retailers and manufacturers the world over use these ISO standards to ensure that barcodes can be read consistently at all levels of the supply chain, improving efficiency and productivity.

A verifier based on ISO standards looks at the symbol in the same way that a scanner does, but it also goes even further by grading the symbol’s quality. The grade ranges from A to F based on how close the symbol is to perfect. The lower the ISO grade, the more likely scanning difficulties are to occur. Whilst the target measurement for all barcodes is ISO grade A, Grade B is often the acceptable minimum for 2D codes and Grade C for 1D codes.

There are actually several steps involved in achieving that one little code:

Many retailers (such as Woolworths, Coles and Metcash) ask for a Barcode Verification Report before working with a supplier. This can be obtained through GS1 Australia’s Barcode Testing Service.

GS1 Australia employs the ISO/IEC method to assess the print quality of a barcode. It also assesses other elements – including size, colour, quiet zones (light margins) and barcode location – that, together, create the perfect barcode.

As a GS1 Strategic Alliance Partner, Matthews has the knowledge and expertise to help you select the appropriate barcode solution for your business, as well as leverage the full benefits of barcodes and GS1 standards. For more information, contact us today on +61 3 9763 0533