Sep 17, 2020 by Mark Dingley

For the health and safety of consumers, Australian manufacturers and suppliers must, by law, determine the shelf life of all packaged food and beverage products.

Australia & New Zealand Food Standards Code states if a product begins to deteriorate in quality or become potentially unsafe to consume within two years of packaging, it must have a date mark indicating how long it will maintain its quality and be safe for eating or drinking.

These 'shelf-life' food safety codes fall into two categories: Use-by date and best before date. When printed on secondary packaging, these date markings act as a guide for consumers and help retailers manage stock turnaround to reduce food wastage.

In this handy guide, we explain which codes you should be using for particular product classes, the general rules, along with an overview of the available coding and marking technology.

As the code suggests, a use-by date marks food and beverage products that must be consumed before the date indicated on the packaging.

Regardless of how a product may look or smell, if the use-by date has expired, the item must be considered unsafe for human consumption because the food may have become unstable, or bacteria may be present.

Due to the potential health or safety risk, packaged food products cannot legally be sold past their use-by date. Because steep penalties apply for non-compliance retailers must rely on manufacturers to mark products with clear and accurate date codes.

Use-by date codes are typically used for high risk and most perishable food items, particularly those requiring refrigeration, such as:

Unlike a use-by date, a product marked with a best-before date may be still safe to be consumed after that date; however, the manufacturer has determined that the quality of the food will start to deteriorate from its peak.

If stored correctly, foods with a best-before date will retain their colour, taste, texture and flavour and be fit for human consumption.

Also, foods and drinks with best-before dates can still be sold after that date, because it should be safe to eat provided the item looks and smells as the consumer expects. Retailers will often discount goods that have past their Best-Before date to make way for new stock.

Use-by date codes are typically marked onto low risk and more stable products, such as:

Even though most consumables will have either a use-by or best-before date, some food categories don't require date marks of any kind; these include:

If you have a consumable product and are still unsure which date code category it falls into we always recommend double-checking the Food Standards Code.

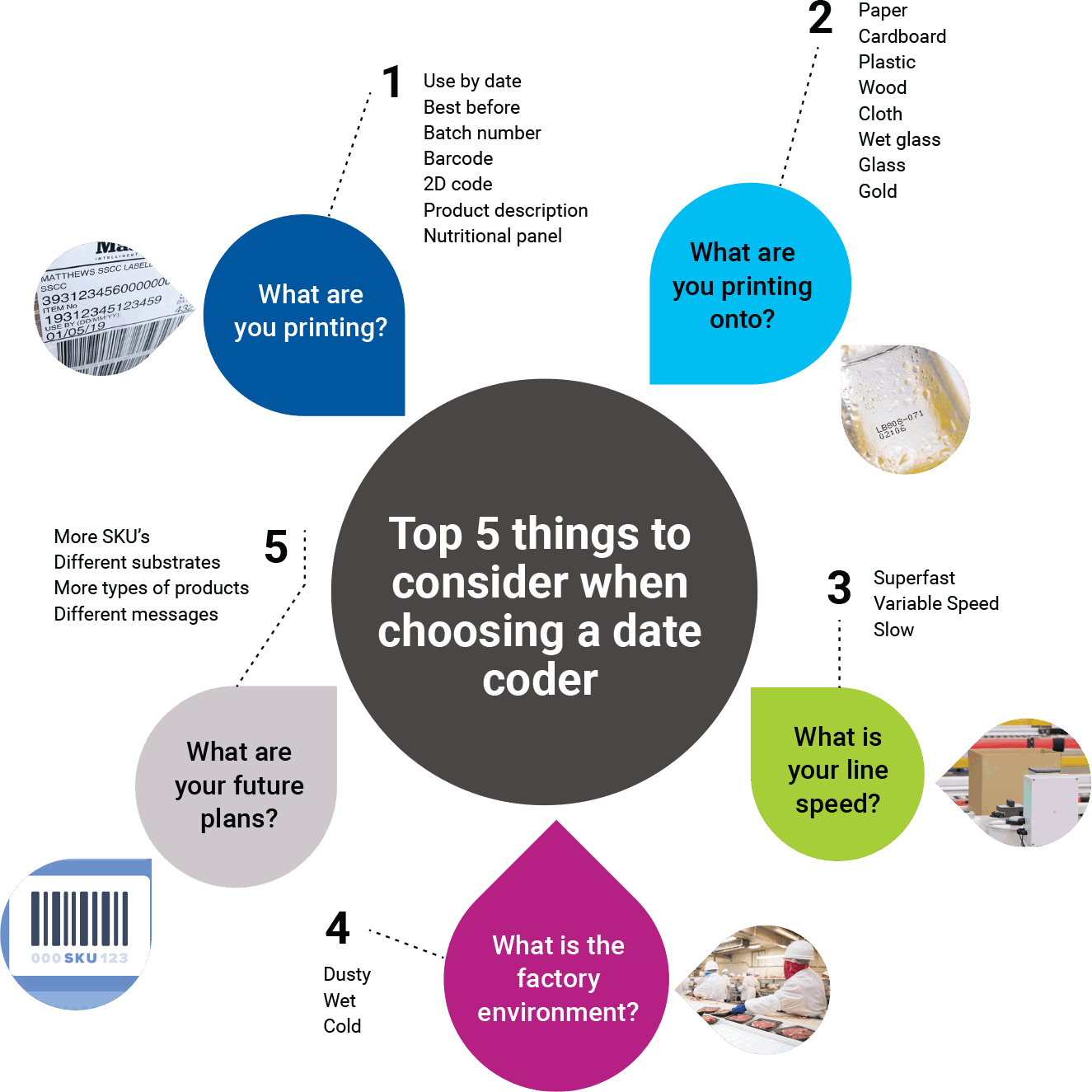

Depending on the type of packaging and your production environment, you have a variety of technologies to help you meet your date coding and batch coding obligations.

Some of the most popular technologies include:

As the industry experts in all things coding and marking for Australian manufacturers, if you need advice on date coding, contact Matthews, one of our friendly team, will be happy to help.